Table of Contents

Introduction

How Oxygen is Made – Oxygen is one of the basic chemical elements. Oxygen in its most common form is a colourless gas found in the air. It is one of the elements that sustain life on Earth and is required by all animals. Oxygen is also used in many industrial, commercial, medical and scientific applications. It is used in blast furnaces to make steel and is an important ingredient in the manufacture of many synthetic chemicals, including ammonia, alcohol, and various plastics.

Oxygen and acetylene burn together to provide the very high temperatures needed for welding and cutting metals. When oxygen cools below -297 degrees Fahrenheit (-183 degrees Celsius), it becomes a light blue liquid that uses as rocket fuel.

How to Make Oxygen

Oxygen is one of the most abundant chemical elements on Earth. About half of the Earth’s crust made up of chemical compounds that contain oxygen, and a fifth of our atmosphere up of oxygen gas. About two-thirds of the human body is up of oxygen. Although oxygen exist since scientific research began, it not discover and recognized as a separate element until 1774, when Englishman Joseph Priestley isolate it by heating mercuric oxide in an invert test tube with concentrated sunlight.

Priestley described his discovery by the French scientist Antoine Lavoisier, who continued experiments and found it to be one of the two main components of air. Lavoisier named the new oxygen gas from the Greek words oxys, meaning acidic or acid, and alginate, meaning production or formation, because he believed it to be an essential component of all acids.

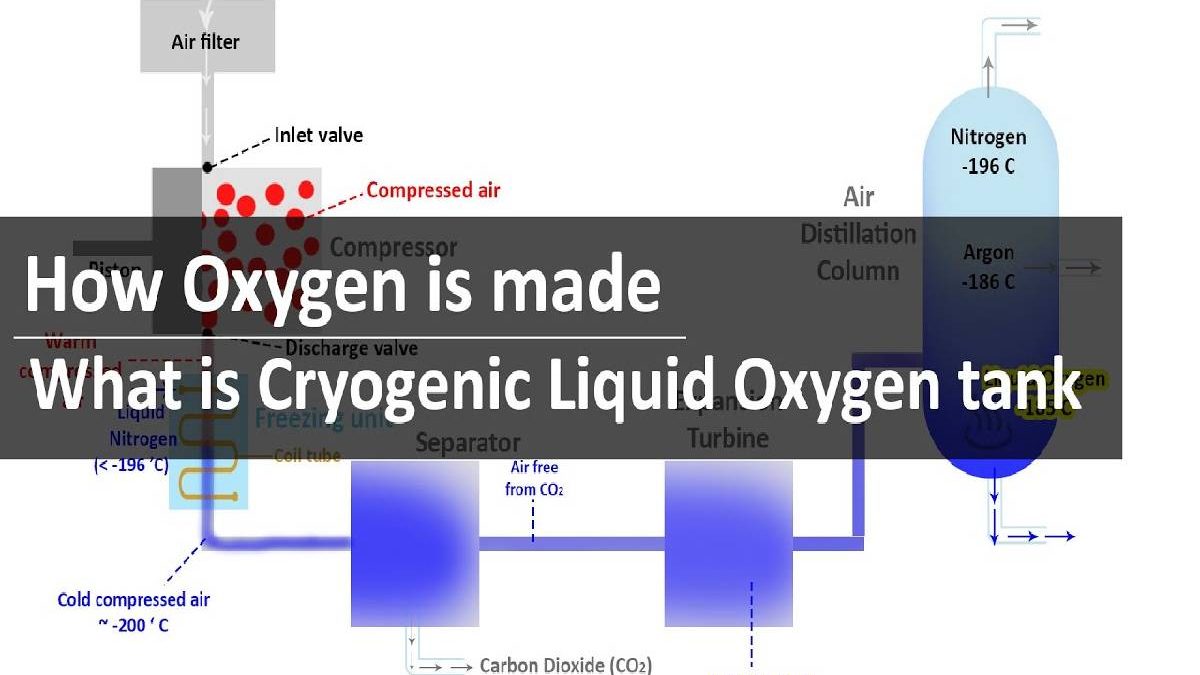

In 1895, Karl Paul Gottfried von Linde of Germany and William Hampson of England independently developed a process for reducing air temperature to the liquefaction point. By carefully distilling liquid air, the various constituent gases can boil and collect individually. This process quickly became the main source of high-quality oxygen, nitrogen and argon.

Raw Materials

Oxygen can made from a number of materials using a variety of methods. The most common natural method is photosynthesis, in which plants use sunlight to convert carbon dioxide in the air into oxygen. This balances the respiration process in which the animals convert the oxygen in the air back into carbon dioxide.

The most common commercial process for producing oxygen is air separation using either a cryogenic distillation process or a vacuum swing adsorption process. Nitrogen and argon also made by separating them from the air.

Oxygen can also form as a result of a chemical reaction in which oxygen release from a chemical compound and becomes a gas. This method uses to generate limit amounts of oxygen to support life in submarines, aeroplanes, and spacecraft.

Hydrogen and oxygen can create by passing an electric current through water and combining the two gases as they bubble. Hydrogen remains produce at the negative electrode and oxygen produce at the positive electrode. This process calls electrolysis and produces extremely pure hydrogen and oxygen. However, it consumes a lot of electrical energy and is not economical for large-scale production.

Manufacturing Procedure

Most commercial oxygen produces using a type of cryogenic distillation process originally developed in 1895. This process produces more than 99% pure [oxygen]. Recently, the more energy-efficient vacuum swing adsorption process has use for a limited number of applications that do not require [oxygen] above 90-93% purity.

Here are the steps for producing commercial-grade [oxygen] from air using the cryogenic distillation process.

Pretreating

Because this process uses an ultra-cold section to separate the air, any contaminants that can solidify — such as water vapour, carbon dioxide, and some heavy hydrocarbons — must remove first to prevent them from freezing and clogging the refrigerant tubes.

Nancy EV Bryk

1. The air comprised of about 94 psi (650 kPa or 6.5 atm) in a multi-stage compressor. It then passes through a water-cooled aftercooler to condense any water Before processing, the air remains pretreated to remove impurities that will clog the cryogenic piping. Once pretreat, the air submit to fractional distillation.

In the fractional distillation process, the components gradually separate in several stages. Because all distillation processes work on the principle of boiling a liquid to separate one or more of the components, a cryogenic section remains required to provide the very low temperatures needed to liquefy the gas components. Once the liquid [oxygen] separates, it is purified and stored.

Before processing, air remains pretreated to remove impurities that will clog the cryogenic piping. Once pretreated, the air remains submitted to fractional distillation. In the fractional distillation process, the components gradually separate in several stages. Because all distillation processes work on the principle of boiling a liquid to separate one or more of the components. A cryogenic section remains required to provide the very low temperatures needed to liquefy the gas components. Once the liquid [oxygen] is separate, it purifies and store.

vapor, and the condensed water remains remove in a water separator.

2. The air passes through a molecular sieve adsorber. The adsorber contains zeolite and silica gel-type adsorbents, which trap the carbon dioxide. Heavier hydrocarbons, and any remaining traces of water vapor. Periodically the adsorber is flush clean to remove the trap impurities. This usually requires two adsorbers operating in parallel. So that one can continue to process the airflow while the other one is flush.